If you are looking for a pipe fitting that will not rust, corrode or leach impurities into your water supply, then stainless steel pipe fittings are the best option. Stainless steel is an alloy of iron and chromium, and it contains at least 10.5% chromium content by mass.

This high chromium content gives stainless steel its corrosion-resistant properties. In addition to being corrosion-resistant, stainless steel is also non-toxic and non-leaching. This means that it will not contaminate your water supply with heavy metals or other impurities. To know more about Eco Fitting & Valve you can browse the web.

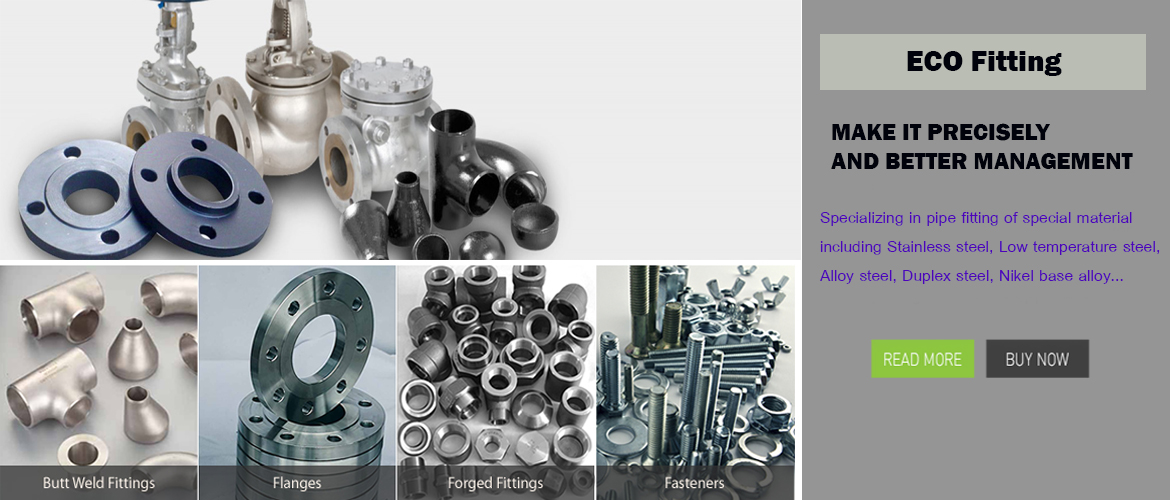

There are two main types of stainless steel pipe fittings: butt weld and socket weld. Butt weld fittings are made by welding two pieces of stainless steel pipe together at their seams. Socket weld fittings are made by inserting a stainless steel pipe into a socket on another piece of pipe or fitting. Both types of fittings provide a strong, leak-proof connection that will not rust or corrode over time.

When choosing stainless steel pipe fittings for your plumbing system, be sure to select the right size and type of fitting for your needs. If you are unsure which type or size of the fitting is best for your project, consult with a professional plumber or contractor for guidance.

There are many types of stainless steel pipe fittings, each with its own unique benefits. Here are the top reasons why stainless steel pipe fittings are the best:

1. Corrosion Resistance: Stainless steel is highly resistant to corrosion and can withstand harsh environments. This makes it ideal for use in corrosive applications such as food processing, chemical processing, and marine applications.

2. Temperature Resistance: Stainless steel can withstand high temperatures without deforming or becoming brittle. This makes it ideal for use in high-temperature applications such as heat exchangers, boilers, and furnaces.

3. Pressure Resistance: Stainless steel is very strong and can withstand high pressures without leaking or bursting. This makes it ideal for use in high-pressure applications such as hydraulic systems and process piping.

4. Chemical Resistance: Stainless steel is resistant to most chemicals and can be used in aggressive chemical environments without fear of corrosion or damage. This makes it ideal for use in chemical processing plants and other industrial applications.

5. Aesthetics: Stainless steel has a clean, modern look that is perfect for architectural and design applications. It is also easy to clean and maintain, making it ideal for use in sterile environments such as hospitals and laboratories.